Biology inspiring astronomy

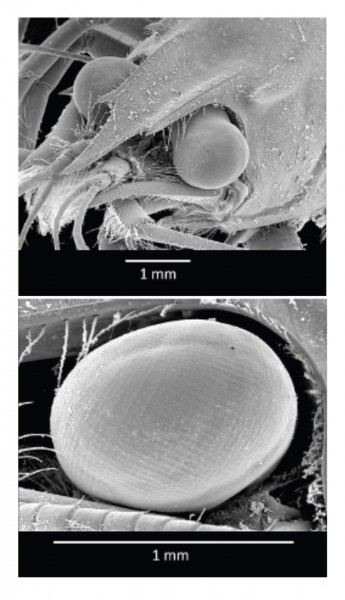

The truly innovative MXT concentrator developed to study GRBs is a system inspired by biology. Crustaceans of the order of decapods, such as the lobster and crab, have indeed a very particular type of vision. In general, vision is based on refraction, on the contrary decapods exploit optical reflection. The light is focussed by a number of small channels which cover the eyes of the decapods: a honeycomb structure, although the shape of these channels is not hexagonal but squared. A ray of light can bounce on the wall of the channel being reflected. Eventually, all rays are concentrated in a single central spot.

The advantage of this system is a wide viewing angle. These particular eyes can practically have an open field of view of 180 °. This is helpful for animals living in depth or in turbid environments with little light: they need to collect as much light as possible to identify more quickly predators or food sources in the surrounding environment.

Application to X-rays

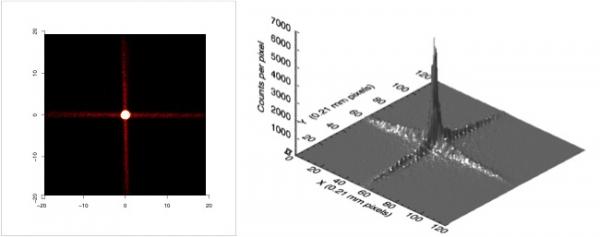

By trying to apply the principles of optics, scientists have realised that this type of vision is only effective if the base of the channels is square. Curiously, this is one of the few examples of a natural square shape in biology. Ideal in low light conditions, high light levels are detrimental. The more rays there are, the more they will be reflected and cause a noisy image on the receiver. This technique prevails when the signal/noise ratio is low, which is the case in the X-ray range. It was in the late 1970s, in Paris, that the first studies were carried out in an attempt to reuse this type of vision for X-ray observation.

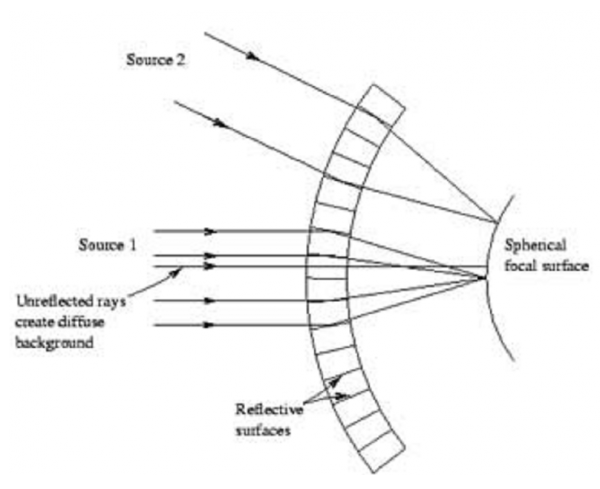

X-rays have the particularity of being difficult to reflect: reflection is only possible at grazing incidence. The microchannel technique is therefore very suitable for this type of photon because a radial structure means that the light is only at a small angle to these surfaces.

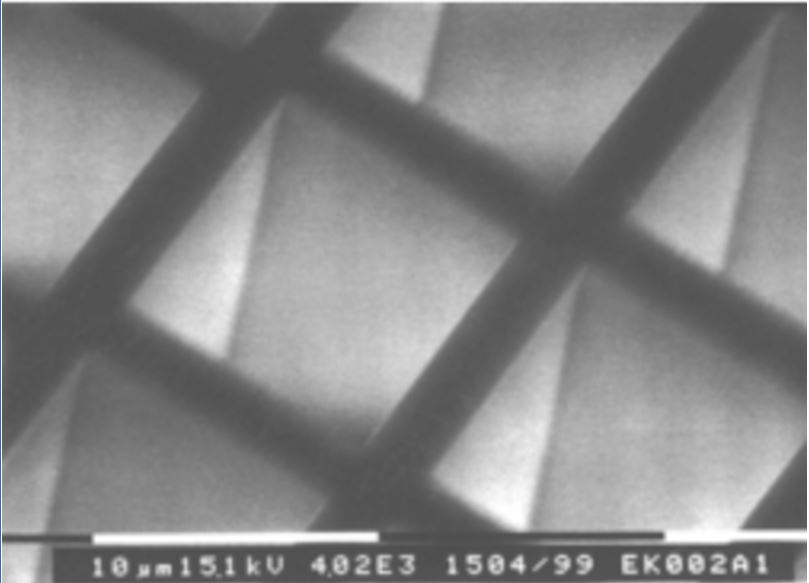

To ensure that the point spread function (PSF) is sufficiently small, the size of each single cell of the optics must be very small but still greater than the characteristic wavelength of the light to be reflected. In the case of X-rays, each cell should have a size of the order of few tens of microns. Making an assembly of micro-channels of such size with a metal structure may be hard. However, other materials can be used to manufacture the channels.

Micro-channels made of glass

Photonis has put its expertise in processing glass for optical applications to the benefit of the SVOM project. A squared block of glass is heated and then stretched by a weight. Stretching progressively reduces the size of the section. By repeating this process, it becomes possible to obtain regular channels with the desired section size. To obtain the hollow base, it is sufficient to use two types of glass during the process: an external glass and an internal glass with different composition. When a section size of 20 microns is reached, it is sufficient to chemically dissolve the internal glass. The thickness of the external glass is then a few microns. A major difficulty in this process is to avoid twisting the glass during stretching. But the work is not yet done! The micro-channels must then be assembled together. The idea is to assemble different fibers together, in packs of 25, before heating and stretching, to reach the size of 20 microns per fiber. This bundle of fibers is then cut along its width at 90 °. A wafer is thus obtained. The wafer itself is then heated for forming it by means of a press: the surface changes from a flat one to a curved one. Cutting the wafer and shaping it are very complicated phases. Even very small defects can cause degradation of the instrumental response.

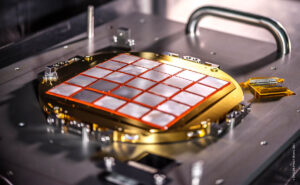

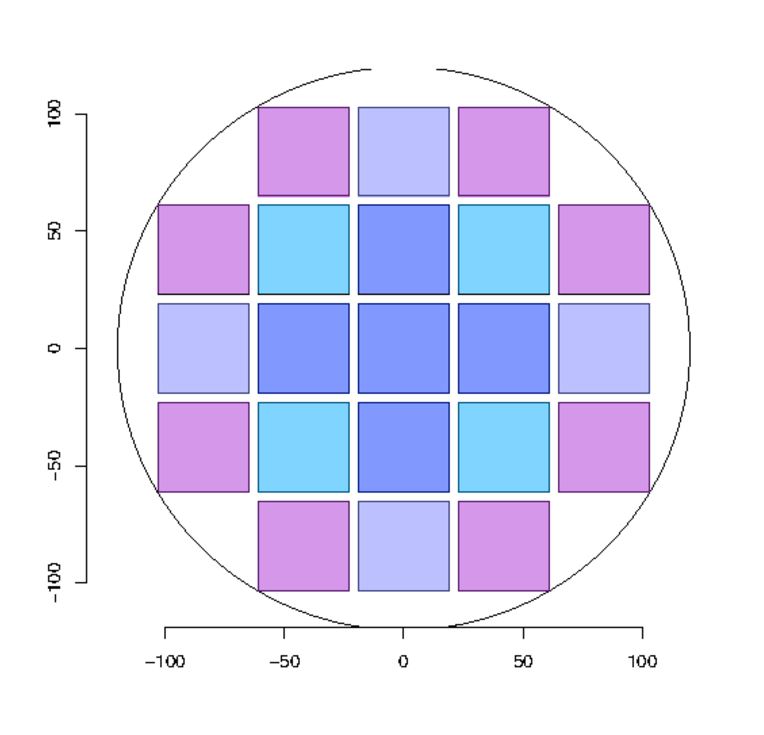

To increase the X-ray reflectivity, the leaded glass the micro-channels are made of is immersed in an iridium bath. In all, six months are necessary to produce the 21 wafers corresponding to the complete optics, if no problems arise during the production.

A great deal of technology

The weight and mass constrains on the SVOM payload suggested the investigation of this type of technology for the observation of X-rays. In fact, the complete optical module developed for SVOM, about 20 cm in diameter, weighs only 1.8 kg. In comparison, the SWIFT SXT instrument developed by NASA weighs several tens of kilos, while the collecting area is only three times larger.

Therefore, this technique seems very promising also for application in future space missions and SVOM, the first one carrying it into orbit, will then represent an interesting case study. Similar optics, but based on silicon pores, are adopted in other projects, such as ATHENA, the future major X-ray observatory developed by ESA to be launched in 2028.